From large poultry farms to local butcheries and supermarkets, ensuring that chicken products are packaged safely and hygienically is critical. Among the many options available, PE chicken wicket bags are one of the most practical and reliable solutions for poultry packaging.

In this article, we’ll explain what PE chicken wicket bags are, and how they help businesses meet both food safety standards and customer expectations.

What Are PE Chicken Wicket Bags?

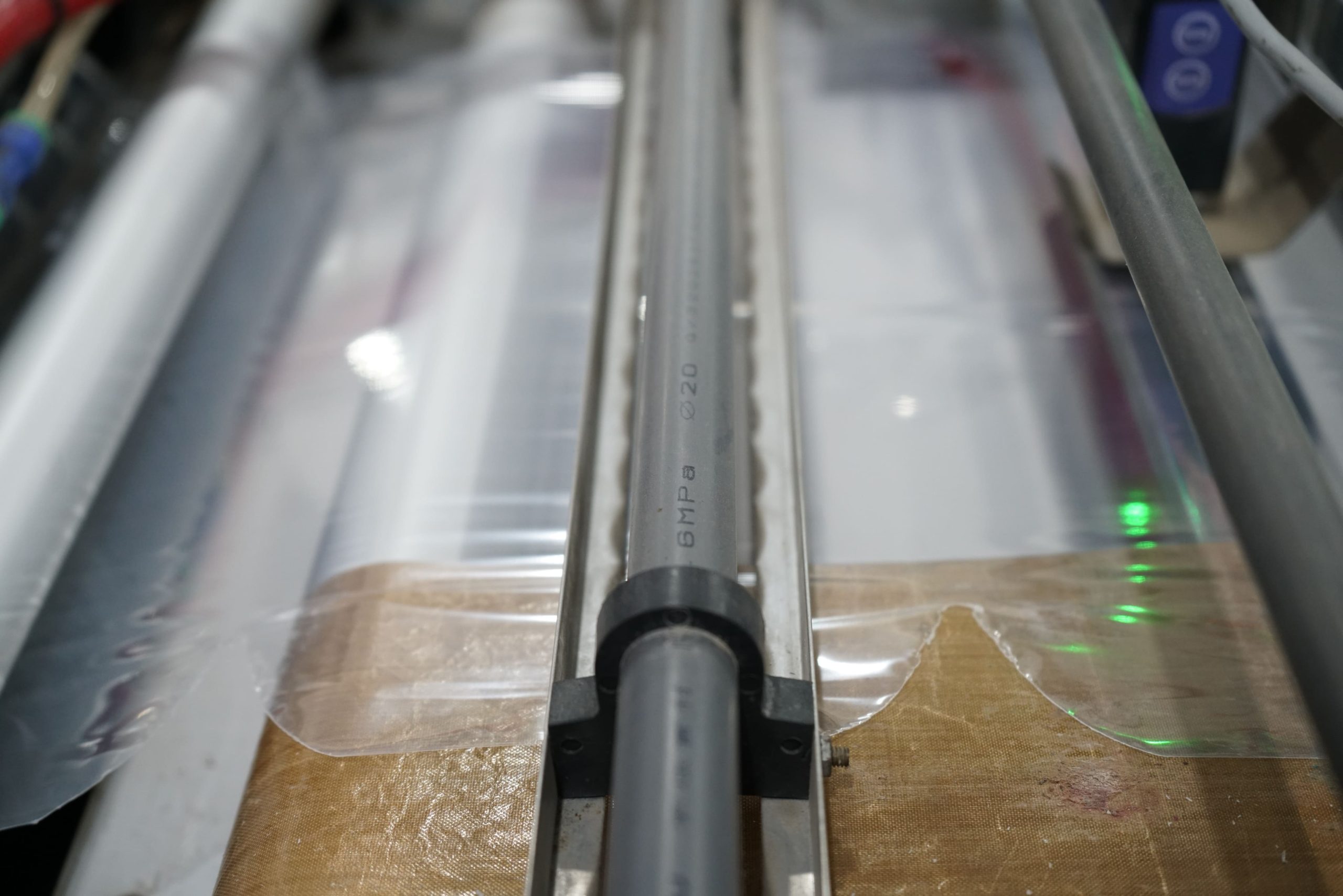

PE (polyethylene) wicket bags are food-grade plastic bags attached to a wire wicket stand or header, allowing for fast and efficient bag loading. They are designed to hold fresh or frozen poultry products and provide:

- Easy dispensing: Bags can be quickly opened and filled, speeding up processing.

- Hygiene: They minimize handling, reducing contamination risks.

- Durability: They resist punctures and tears, even when packaging whole chickens.

- Versatility: Suitable for fresh, chilled, or frozen poultry products.

Why The Poultry Industry Relies on PE Wicket Bags

- Food Safety First

Poultry packaging must meet strict hygiene requirements. PE wicket bags are made from food-grade material that protects chicken from external contaminants, moisture, and bacteria.

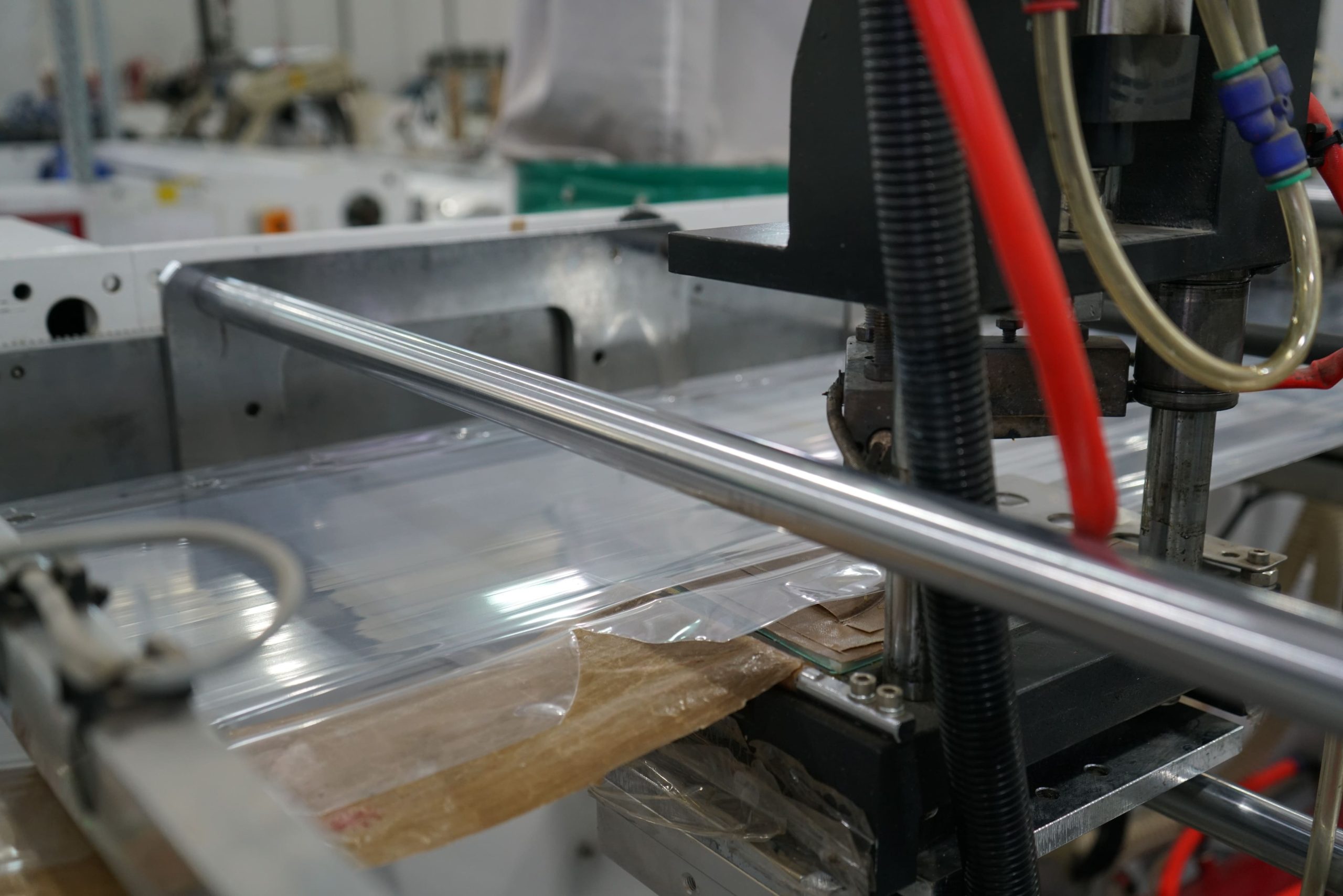

- Efficiency in Processing Plants

Large poultry processors need to move quickly. Wicket bags make packaging faster, saving labor time and reducing bottlenecks on production lines.

- Strength for Transport and Storage

Whether chicken is stored in cold rooms or transported to retailers, packaging must remain strong. PE wicket bags are engineered to handle freezing and heavy handling without breaking.

- Shelf Presentation

With high clarity, these bags keep chicken visible and attractive on shelves, boosting consumer confidence and sales.

- Custom Printing Options

Producers and retailers can brand their bags with logos, product details, or compliance information — helping stand out in a competitive market.

Key Benefits of PE Chicken Wicket Bags

- Food-grade, hygienic material

- Tear and puncture resistant

- Available in multiple sizes and thicknesses

- Suitable for fresh and frozen poultry

- Easy to load, seal, and store

- Fully printable for branding and labeling

Choosing the Right Supplier

When sourcing PE chicken wicket bags, it’s important to ask suppliers about:

- Sizes and customization options (for different poultry products)

- Lead times and delivery schedules (to align with production cycles)

- Food safety certifications (to meet regulatory requirements)

- Printing and branding services (for retail-ready packaging)

Working with an experienced packaging manufacturer ensures you get consistent quality and a reliable supply chain — essential for busy poultry operations.

Conclusion

PE chicken wicket bags are more than just packaging — they’re a critical part of the poultry supply chain. They ensure hygiene, efficiency, and durability while offering branding opportunities that help products stand out on store shelves.

For farms, processors, and retailers alike, investing in the right poultry packaging is an investment in both food safety and customer trust.